Automotive industry

Role of high performance plastics

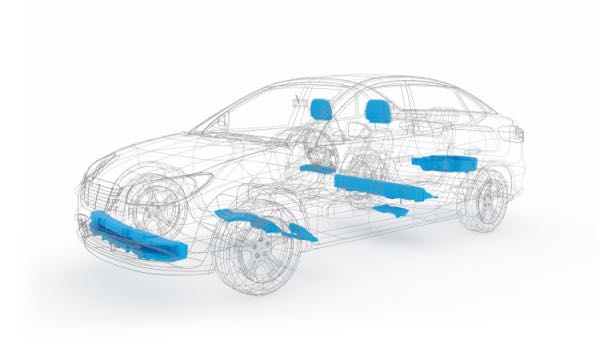

The light weight of plastics makes for more fuel efficient vehicles. It is estimated that every 10% reduction in vehicle weight results in a 5% to 7% reduction in fuel usage. Current economic and environmental concerns make the creation of more fuel efficient cars a top priority in the automotive industry. The use of modern materials like aluminum and carbon fiber are helpful, but the wise allocation of plastics are making an increasing difference. Some other advantages of high performance plastics used in transport vehicles include:

- minimal corrosion, allowing for longer vehicle life

- substantial design freedom, allowing advanced creativity and innovation

- flexibility in integrating components

- safety, comfort and economy

- recyclability

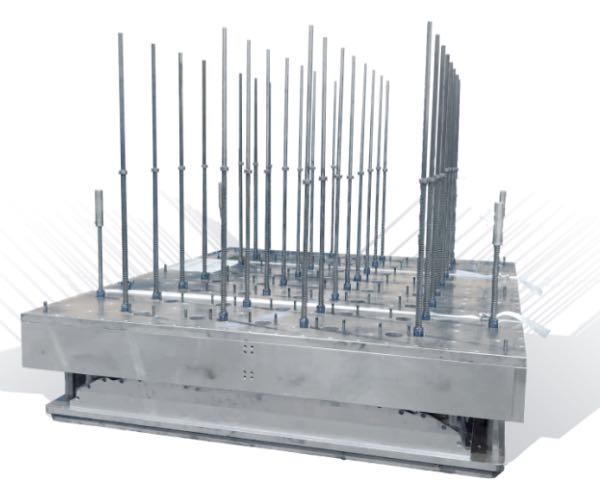

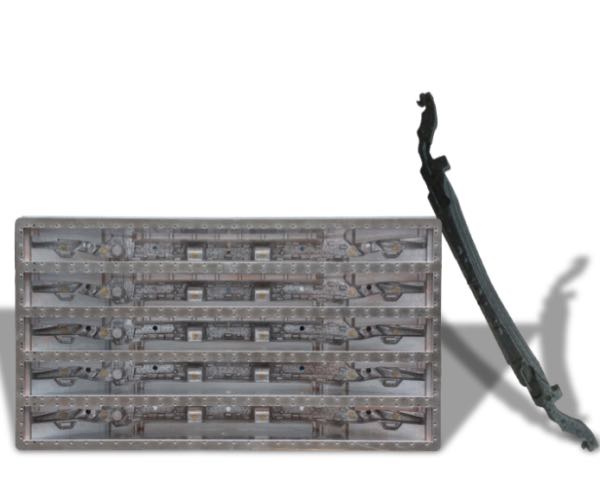

Expanded Polypropylene (EPP) Polypropylene is a thermoplastic polymer used in a wide variety of applications. A saturated addition polymer made from the monomer propylene, it is rugged and unusually resistant to many chemical solvents, bases and acids. *Application: automotive bumpers, chemical tanks, cable insulation, gas cans, carpet fibers.

Polyurethane (PUR) Solid Polyurethane is an elastomeric material of exceptional physical properties including toughness, flexibility, and resistance to abrasion and temperature. Polyurethane has a broad hardness range, from eraser soft to bowling ball hard. Other polyurethane characteristics include extremely high flex-life, high load-bearing capacity and outstanding resistance to weather, ozone, radiation, oil, gasoline and most solvents. Application: flexible foam seating, foam insulation panels, elastomeric wheels and tires, automotive suspension bushings, cushions, electrical potting compounds, hard plastic parts.

Expanded Polystyrene (EPS) Naturally clear, polystyrene exhibits excellent chemical and electrical resistance. Special high gloss and high impact grades are widely available. This easy to manufacture plastic has poor resistance to UV light. Application: equipment housings, buttons, car fittings, display bases.

Thermal insulation

Chemical resistance

Mechanical resistance

Lightness

Floatability

Soundproofing

Packaging industry

Food active packaging

The packaging industry plays a key role here in terms of shelf life and protection of food. The focus is on the development of "active packaging" that extends the shelf life and thus reduces food waste and losses.

Intelligent indicators (freshness, time temperature indicator, opening, etc.) should help the consumer to assess product safety beyond the printed expiry date. The cycle is closed by intelligent recycling systems that are able to separate food components from packaging in order to make them usable for a wide variety of recycling processes.

Consumers look to buy food that is fresh and attractive adn often from the other side of the globe. In order to prevent fruit, vegetables and many other items from losing their flavor and crispiness on their way to the supermarket, they must be kept cool for as long as possible. Special boxes made of EPS take care of this job. Air-filled cells give EPS particularly good insulating properties. For example: the temperature in an EPS transport box filled with ice will remain constantly low for many hours. Transport boxes made of EPS are particularly hygienic and transfer no aromas to the contents – in other words, they are the ideal packaging for food. For hot and cold – the excellent insulating properties of EPS packaging keep products cold or warm for a longer period of time, whatever their particular job may be.

HVAC protective packaging

HVAC/R application system design is becoming increasingly complex. Saving energy and regulatory changes govern market demand. Combining energy efficiency and keeping production costs optimised is a priority. As such, we regularly develop product concepts combining the following features for our partners:

- Thermal insulation

- Soundproofing

- Air- and water-tightness

- Fire resistance

- Surface aspects

Besides plastic injection already recognised for its benefits, various closed-cell foams are perfectly in line with market expectations. These materials combine thermal insulation, a lightweight design, and mechanical strength. They make it possible to design high-performance units that are easy to implement on production lines. EPP, for example, with its mechanical properties and resilience makes it possible to replace conventional sheet metal and overlay insulation manufacturing solutions advantageously.