5-axis machining

Manufacturing of complex shape components

In the last decades CNC TVAR has developed into one of the major European third party suppliers able to provide high precision machining of large and complexly shaped parts. Since the very beginningwe have focused on power industry and moulds and tools.

CAD construction

Construction of EPS, EPP, PUR tools and control jigs

Tools and jigs can be produced in many different ways. Our goal is to choose the one that provides the highest quality while keeping the cost as low as possible. Our experienced engineers work with wide range of industry standards and formats are able to cover the customer needs using the groundbreaking tools:

- SolidWorks

- Catia

- PowerMill

Go to CAD construction of moulds & tools>

Go to CAD construction jigs & fixtures>

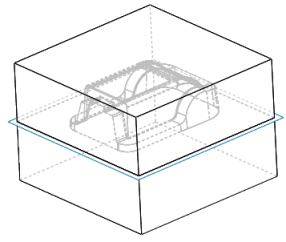

Assembly

Our assembly team can handle any mould or control jig design

Mold assembly is one of the most critical steps of mold making procedure, all the parts machined or purchased need to be put together and required to be work functionality. Mold assembly job requires comprehensive understanding of mold structure as well as molding process. Quality of mold assembly determines the mold precision, productivity.

- Surface polishining

- Sharp edges control

- Assembly of all parts

- Mechanism functionality control

- Scanner control

Absolute Arm 7-Axis

The all-in-one solution for portable 3D measurement

The flagship of the Absolute Arm range, the Absolute Arm 7-Axis delivers tactile probing and laser scanning in a uniquely ergonomic package. It’s the clear choice for high-end portable measurement applications.

- 7-axis

- High Speed - On fly tools swapping - No need for recalibration

- Extreme Precision (ISO10360-12) - Touch probe - Laser scanner

- High Data Quality - 150mm scan line - 752.000 measured points/s

Non destructive testing

Detection and evaluation of the part surface condition according to the highest standard

Whether you need VT method focused on the detection of cracks, undercuts, and surface porosity, MT discovering material discontinuities on ferromagnetic materials, PT for checking surface opened imperfections, or UT for discovering inner cracks, our team of certified personell can analyze your components.

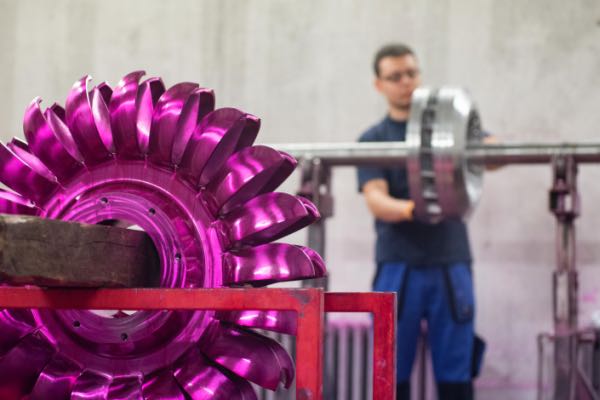

Balancing of rotors

Balancing from proffesionals

The balancing machine shows the actual unbalance in one or two planes by graphical and numerical output. An inherent part of the balancing process is the weight correction design and verification of the performed correction. We offer weight reduction by drilling holes or grinding of defined areas as well as mass addition by welding or mechanical counterweight assembly.

Go to balancing >