Top quality metrology solution

CNC TVAR metrology hardware captures quality data for measurement, positioning and inspection. It is the key bridge between the real and virtual worlds, bringing real-world data into the digital domain. Our measurement technology is helping us with the feedback for our production and also creates great visual control outcome for our partners

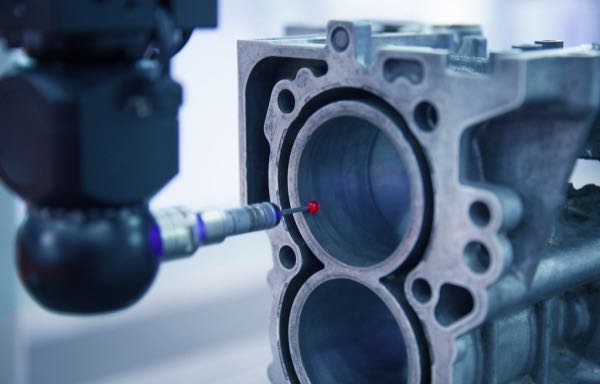

DEA ALPHA 2.0

Flexible Gantry Coordinate Measuring Machine for Large Workpieces

Best fit dimensions measurement or measuremnt of the finally machined components, both can be performed on our coordinate measuring machine, where we can measure all components up to 5 meters of diameter.

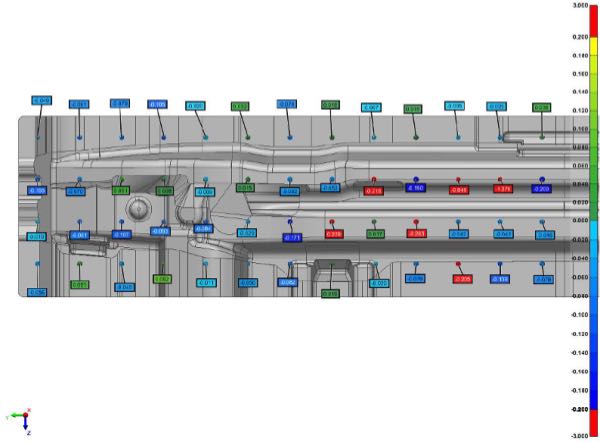

- Measurement of shape and dimensions and comparison with a drawing

- Measurement of shape and dimensions and comparison with a CAD data model

- Part alignment based on RPS points or according to individual requirements

- Reverse engineering = surface scanning (generation of data model based on a solid part)

- DEA Alpha: 5,000/3,000/1,500mm Touch probe

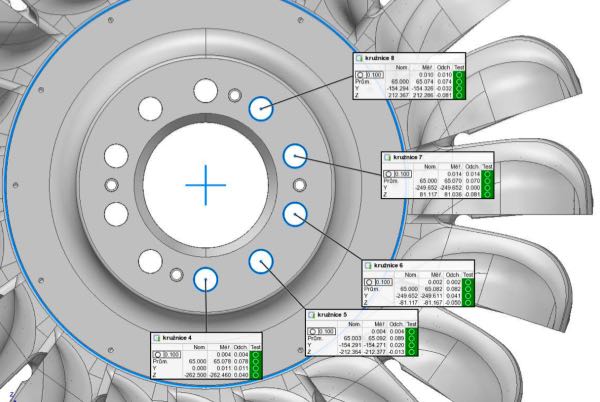

- Rotors

To ensure the efficiency of the power plant, compressor or a ship, we measure all rotors with a CMM which enables us to control every dimension and react accordingly during the manufacturing process.

Type Max. size Pelton runners 3.600mm Francis runners 3.600mm Turgo runners 3.600mm Kaplan runners 3.600mm Impellers 3.600mm Propellers 3.600mm - Moulds

- Control jigs

- Components

Absolute Arm 7-Axis

The all-in-one solution for portable 3D measurement

The flagship of the Absolute Arm range, the Absolute Arm 7-Axis delivers tactile probing and laser scanning in a uniquely ergonomic package. It’s the clear choice for high-end portable measurement applications.

- 7-axis

- High Speed - On fly tools swapping - No need for recalibration

- Extreme Precision (ISO10360-12) - Touch probe - Laser scanner

- High Data Quality - 150mm scan line - 752.000 measured points/s

- Rotors

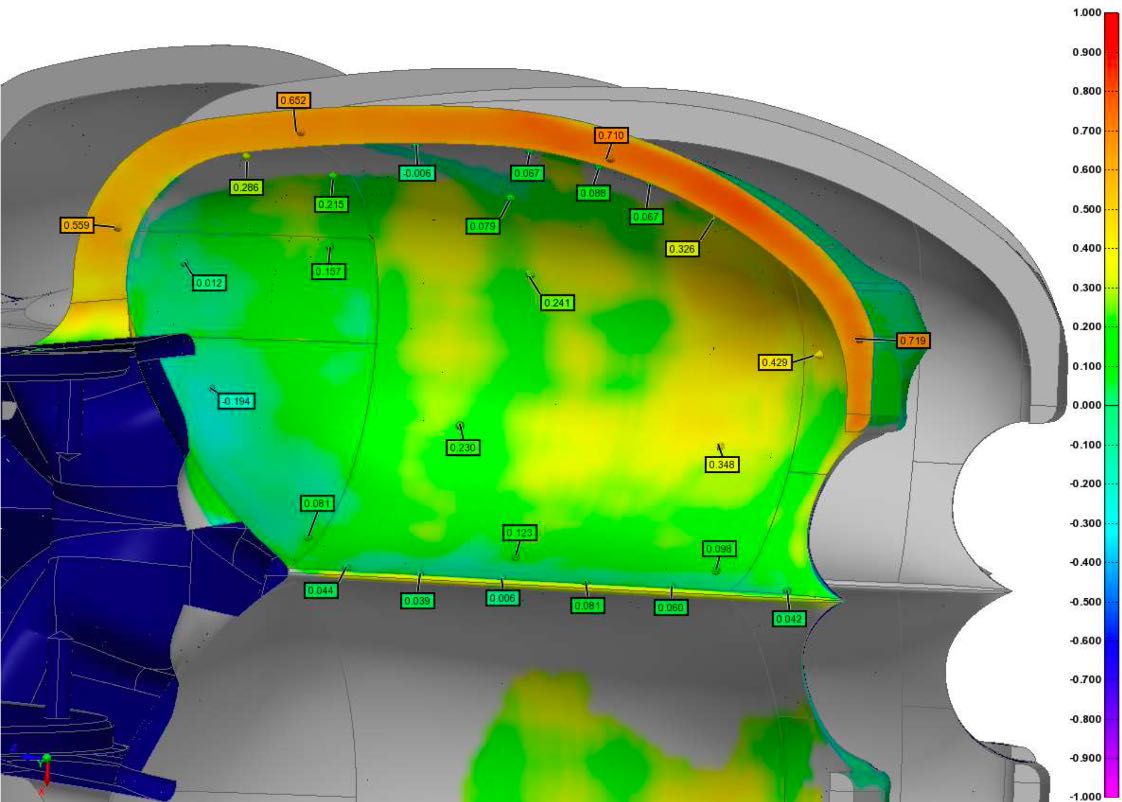

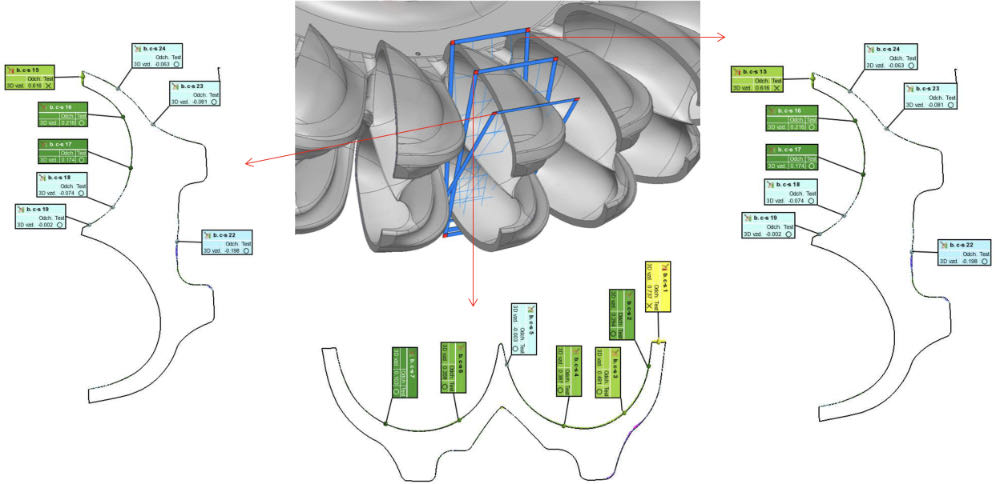

To ensure the surface precision, which has a direct impact on the efficiency of the power plant, compressor or a ship, we measure all rotors with a laser scanner which is used as a base for precise manual polishing. Thanks to laser scanner cuts we can even substitute classic measurement templates.

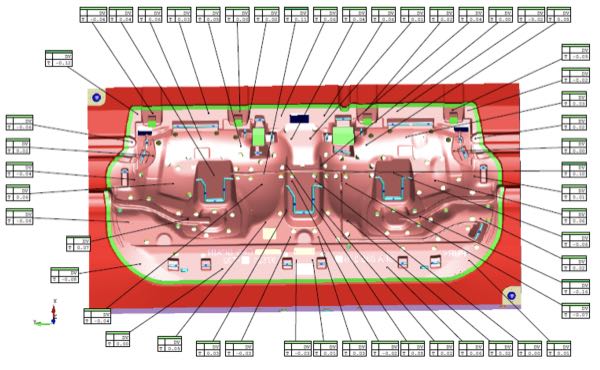

Type Max. size Pelton runners 3.600mm Francis runners 3.600mm Turgo runners 3.600mm Kaplan runners 3.600mm Impellers 3.600mm Propellers 3.600mm - Moulds

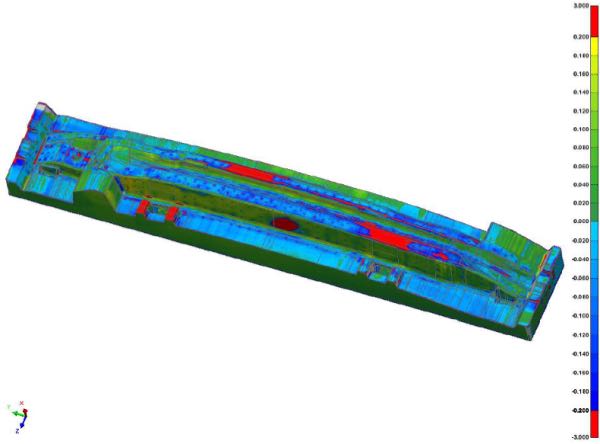

Measurement of moulds and tools enables us to ensure the quality of the PUR / EPP / EPS components in your production process and making your life easier.

Type Max. size PUR moulds 3600mm EPP moulds 3600mm EPS moulds 3600mm - Control jigs

To ensure the precision of control jigs, we measure them, to make sure your control process has a solid base.

Type Max. size Metal parts control jig 3600mm Plastic parts control jig 3600mm Complex parts control jig 3600mm - Components