Experience in motion

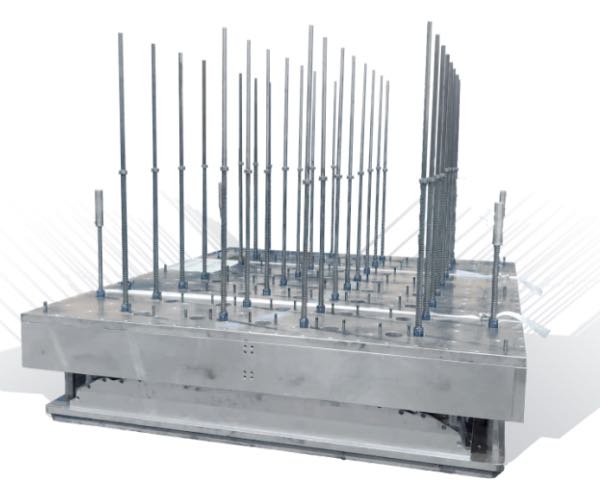

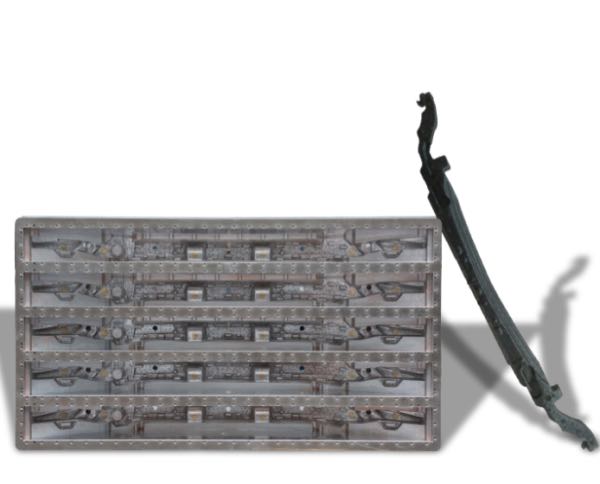

Our assembly team can handle any mould or control jig design

Mold assembly is one of the most critical steps of mold making procedure, all the parts machined or purchased need to be put together and required to be work functionality. Mold assembly job requires comprehensive understanding of mold structure as well as molding process. Quality of mold assembly determines the mold precision, productivity.

- Surface polishining

- Sharp edges control

- Assembly of all parts

- Mechanism functionality control

- Scanner control