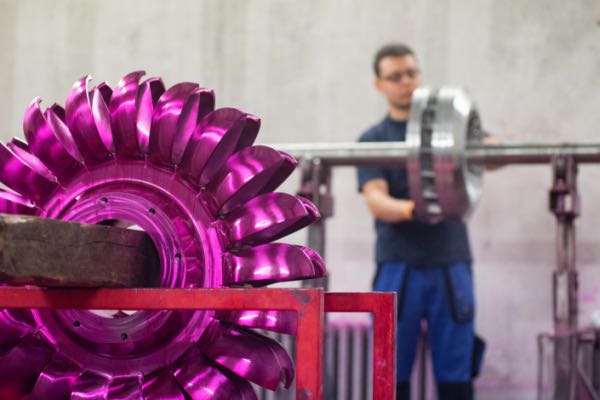

Runners according to your design

Forged monoblock Francis runners from CNC TVAR

Rotor is the heart of any turbine. It is a center where the fluid strikes and the tangential force of the impact causes the shaft of the turbine to rotate, producing torque. Close attention to design of blade angles at inlet and outlet is necessary, as these are major parameters affecting power production. This is why CNC TVAR manufactures all runners from a forged blocks consisting of premium alloys no matter the number of blades, size, or rotor design. We understand the need for the highest possible efficiency and make sure, it is not just on the paper. Thus, CNC TVAR provides a long-lasting, high-quality product.

MONOBLOCK solution * High Accuracy – High Efficiency * No Welding – No Deformation SPLIT version * Faster Lead Time

EXPERIENCE

>1.000

runners delivered

HEAVY WEIGHT

50t

maximum disc weight

FLEXIBILITY

3.500mm

maximum runner diameter

Material procurement

Purchasing of stainless steel, titanium and aluminium from top European suppliers. Delivery time depending on specifications and size.

- Forged disc - any size

- Forged disc - 8-14 weeks from order

- Forged disc cut from a bar - up to 1350 mm

- Forged disc cut from a bar - 1 week from order

Go to material procurement >

Manual polishing

Grinding and polishing – thatʼs where the parts get their final touch. When it comes to the surface quality of complex shapes, we do not make any compromises.

- Polishing based on CMM measurement report

- Experienced employees polishing according to customer specific procedures

- Several dimensional and quality controls through process

- Compliance with all environmental standards thanks to the newest filtering technologies

Non-destructive testing

Completed products are checked using four non-destructive testing methods (NDT). Our inspectors are ISO 9712level II certified.

- Visual Testing (VT)

- Liquid Penetrant Testing (PT)

- Magnetic Particle Testing (MT)

- Ultrasonic Testing (UT)

Go to non-destructive testing >

Balancing

The actual unbalance is displayed in one or two planes by graphical and numerical output. There is also a deviation from the allowed unbalance displayed and a suggestion for the most convenient weight correction.

Go to balancing >

3D measurement

The measurement is performed on CMM or with a 7-axis high speed 3D arm with a laser scanner with extreme precision according to the highest international standards.

- Measurement of drawing dimensions

- Measurement of hydraulic profile

- Part alignmenet based on RPS points

- High data quality

Go to measuring >

- Cardano

The hydroelectric plant of Cardano connects and put into the network the energy produced in the North-East of Alto Adige, ensuring the supply to the national grid.

Customer Voith & Alperia Location Italy Scope forged crown & band of 4 Francis runners Runner diameter 2750 mm Installed capacity 180 MW - Trollheim

Trollheim power plant is located in Surnadal Municipality, Møre og Romsdal County. It entred into operation in 1968. Trollheim power plant uses a height of fall of 402 metres from Follsjøen, which is regulated between 420 and 375 metres above sea level. After being used in production in the power plant, water is discharged into the Surna River.

Customer Rainpower & Statkraft Location Norway Scope forged crown & band of a Francis runner Runner diameter 3250 mm Installed capacity 130 MW - Wampu

The Wampu Hydroelectric Power Plant in Indonesia has been put into commercial operation as the outcome of South Korea’s first privately-financed hydropower generation project abroad. It is a run-of-river project located on Biang River in North Sumatera, Indonesia. Wampu Electric Power is a grid connected hydro power plant and supplies zero emission power to the Sumatera grid.

Customer Andritz & PT. Wampu Electric Power Location Indonesia Scope 3 monoblock Francis runners Runner diameter 1350 mm Installed capacity 46,8 MW