CNC TVAR s. r. o. in Czech TOP 100

> For the first time in company history, CNC TVAR has been voted one of the most successful companies in Czech Republic.

Stráž nad Nisou, 15.12.2021 – CNC TVAR becomes 82nd most successful company in Czech Republic. The ceremony took place in the Spanish Hall at Prague Castle. The selection of the top 100 companies is made through a voting process involving approximately 25,000 written responses from the economic and political spheres

“This is an important achievement for our company, primarily thanks to the high work effort of all our employees, who are the foundation of our company’s success” said Tomáš Meruňka, CNC TVAR Chief Executive Officer. We are particularly pleased to get this award this year before celebrating the 15th company anniversary. It is a significant milestone in the short history of CNC TVAR and we already strive to achieve the future company goals.

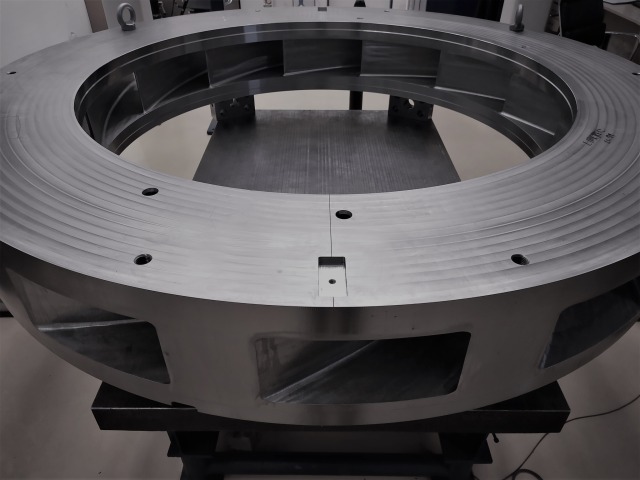

For years we focus on the global power industry. Today`s demanding market seeks for flexibility, reliability and cost effective manufacturing solutions. We have a perfect balance of all those elements and we challenge ourselves to deliver sustainable products for the most demanding markets of todays world. Nowadays, we dispatch one hydro turbine every day, and we seek to even increase the numbers and expand to new market segments in the upcoming years.